Defect Detection and it's Importance in Industry

by Amol Wankade, Google Cloud AI Platform and Google research

Defect detection in manufacturing is the process of identifying flaws or imperfections in products during the production process. These defects can range from visual imperfections such as scratches or dents, to functional issues such as faulty wiring or misaligned components.

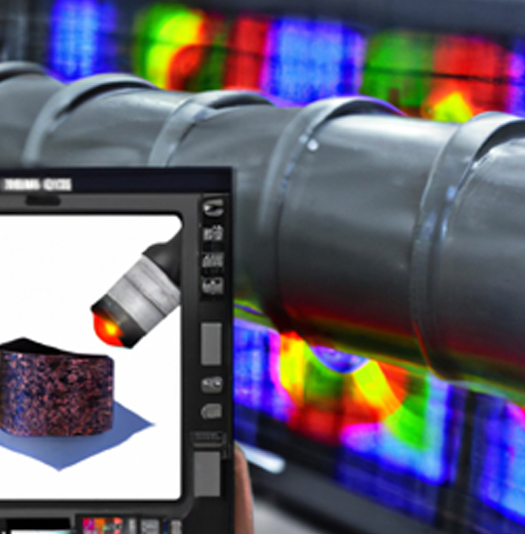

One common method for detecting defects is through the use of computer vision and specialized cameras. These cameras are typically installed in strategic locations on the production line and are used to capture images of the products as they move through the process.

The images are then analyzed by an on-premise computer that has been trained with machine learning algorithms to identify defects. The computer compares the images to a set of "normal" or acceptable images and looks for deviations that may indicate a defect.

One advantage of using computer vision for defect detection is that it can be done in real-time, allowing for immediate correction of any issues that are detected. This can help to reduce waste and improve overall eficiency in the production process.

One way to improve the accuracy and eficiency of defect detection systems is through the use of edge AI. Edge AI refers to machine learning models that are trained and deployed directly on the device that is being used for data collection, rather than in the cloud. This allows for faster processing of data and can be especially useful in situations where there is a need for low latency or where an internet connection is not available.

To deploy a machine learning model from the cloud to the edge, it is first trained in the cloud using a large dataset. Once the model has been trained, it can be "frozen" and exported to the edge device. The frozen model can then be used to make predictions on new data that is collected by the device.

In the case of defect detection in manufacturing, the use of edge AI can allow for faster processing of images and more accurate detection of defects. It can also help to reduce the amount of data that needs to be transmitted to the cloud, which can save on bandwidth costs and improve the overall eficiency of the system.

Overall, the use of computer vision and edge AI for defect detection in manufacturing can help to improve the quality of products and increase eficiency in the production process.

Imtex Registration